This is how I make my own fire pistons out of normal commercially available hardware store material. There are, off course, numerous other ways to make working fire pistons.

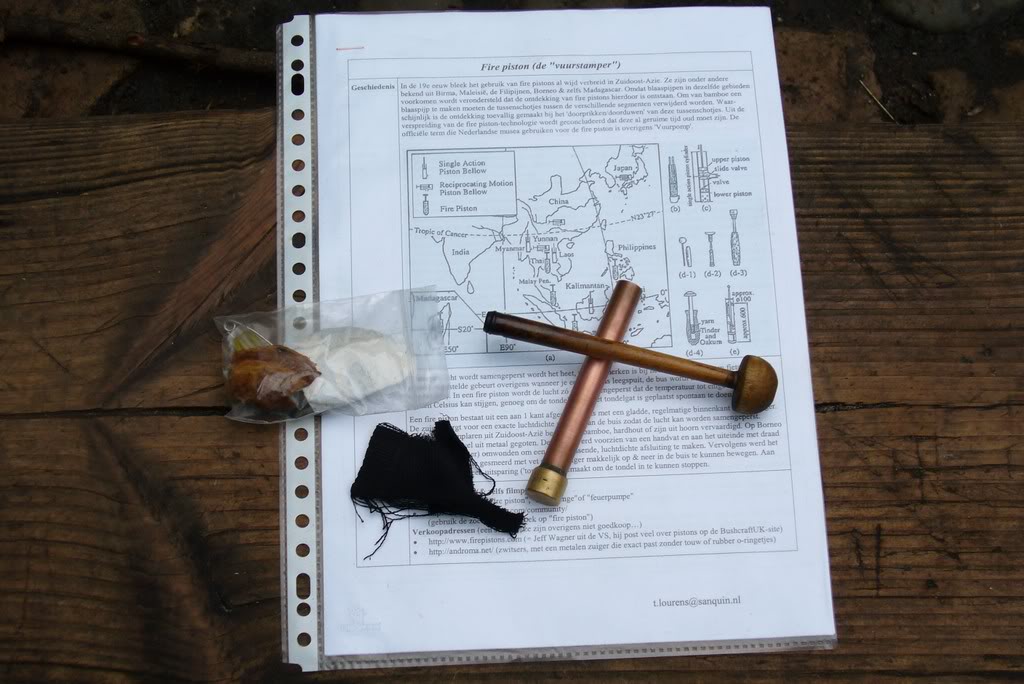

Materials needed:

• Copper tubing Ø 12 mm (inside ± 10 mm)

• Brass end cap for 12 mm tubing

• Wooden piston rod (± 10 mm)

• Wooden knob

• Rubber o-ring (Ø <10 mm)

• Saw for metal

• File or sandpaper

• Good glue (or soldering gear)

• Oil or grease (for lubrication)

• Charcloth or other tinder

• Drill bits 4-7 mm, 10 mm and conical shaped sanding bit for tapering (optional)

Method

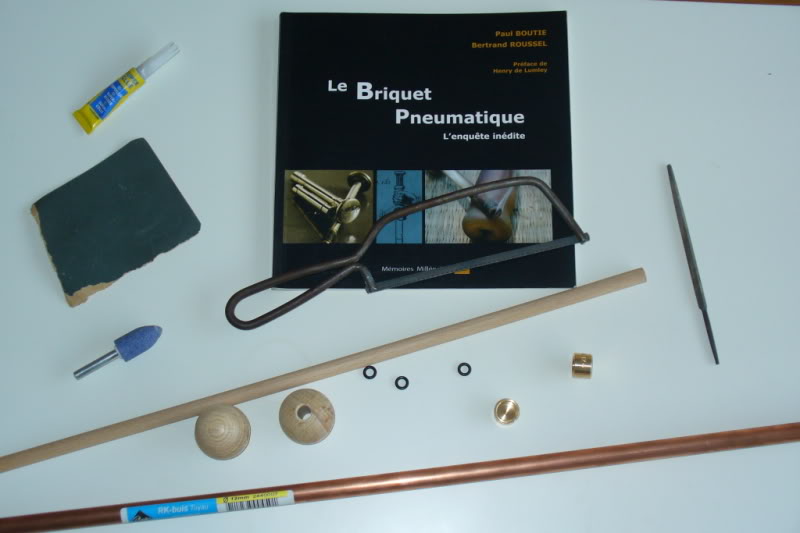

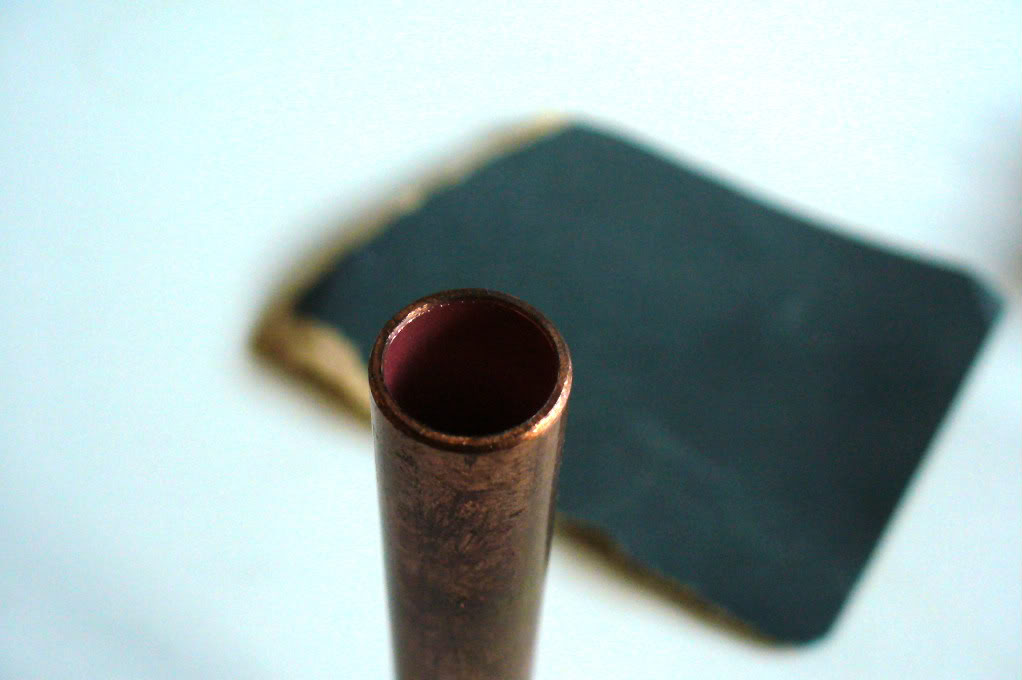

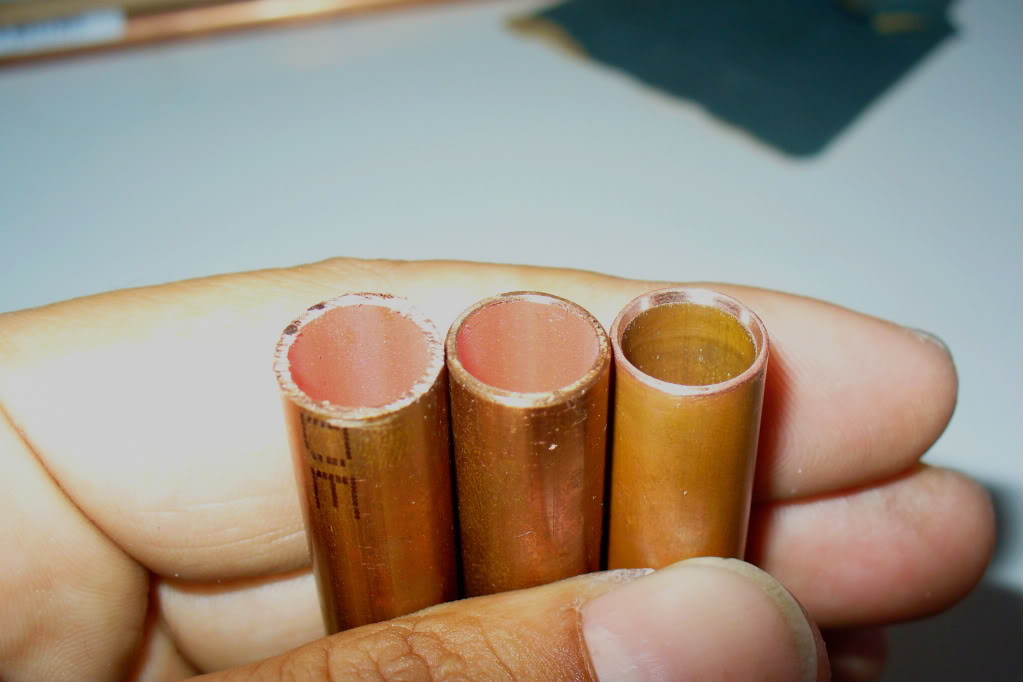

Use the saw to cut off a length of copper tube ± 9-12 cm (the inside is smooth enough of itself).

Use a file or sandpaper to smoothen the rough saw cuts on both ends.

To allow easy entrance of the piston rod, taper the first 1-2 millimeters of the inside on one end with a special drill bit, a file or a piece of sandpaper folded into a cone. Remove any metal dust.

Rough, smooth and tapered:

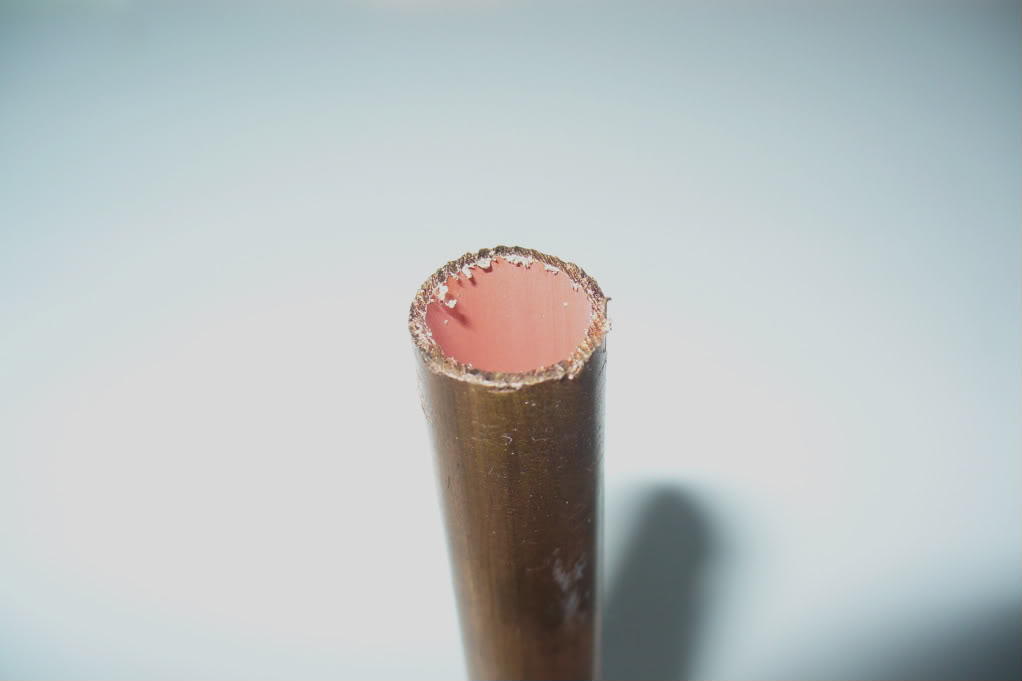

Solder or glue the brass end cap onto the smoothed (not the tapered!) end of the copper tube. The tube is now finished. Another option for sealing the tube at one end is to plug the end with a piece of wood or metal rod. Make sure the wood is treated with super glue or something similar to make it non-porous.

Saw the rod to the correct length (a few centimeters longer than the tube). Smoothen the rough saw cuts with sandpaper.

Insert the piston rod (just as a drill bit) into a hand drill power tool. You can now let the rod spin and use a file or fine toothed saw to make a smooth and even ringed incision at ± 2-3 mm off the end of the piston rod (if the rod is just a bit too thick for the tube). You can also sand it down very evenly by using this method.

This incision is meant for the O-ring and both have to match exactly. The purpose is to get an even incision that is the exact same depth all around the rod. If this is not the case, the rubber O-ring will stick out at some place or leakage will occur underneath the O-ring when trying to compress the air inside the piston. It is a precise job and it requires lots of trying out by putting the O-ring in place and trying to make it slide into the tube. When searching for the perfect fit, the piston rod should be entering the tube without trouble and moving freely up and down the piston tube (use oil or fat as lubricant) with not too much resistance when pushed. The groove can also be made by hand. Hold the file or saw in the same position as the picture and turn the rod with the other hand.

Drill a shallow hole into the working end of the piston rod (the end with the rubber O-ring), 4-7 millimeters wide with a depth of a few millimeters. This is the "tinder cavity" or tinder cup in which the tinder is placed.

As most woods are porous, you'll have to make the tinder cup and surrounding rim airtight by applying some super glue. Several thin layers may be needed. Make sure that the O-ring isn't glued! Let it dry.

Drill a hole in the wooden knob and glue (or screw) it onto the hand held end of the piston rod. Make sure the piston rod is still long enough to reach the bottom of the tube.

Put some lubricant on the O-ring and test the air compression of the piston by inserting it into the tube.

When you try to push it in fast, you should feel the "cushion" of compressed air at the end of the stroke that forces the piston rod to bounce back. In the ideal case, you shouldn’t be able to touch the bottom of the tube with the piston rod. Not even when pushing it in slowly. Most of my working fire piston do this only when I push the piston rod in very fast. So don’t despair if yours is leaking air at a slow speed. If there is no rebounce, apply more layers of super glue and check the attachment of the end cap. If you do feel the "air cushion", you are good to go.

The piston after rebounding:

Fill the tinder cup with charcloth (I roll a little piece into a loose ball and push it in) or other good tinder. Lubricate the rubber O-ring and place the piston rod in the tube.

The most ergonomic way of striking is to put the tube upright on a hard surface, holding it steady with one hand. Use the palm of the other hand to push the piston rod with a forceful and (very important) speedy stroke into the tube. Pull it out again by gripping the wooden knob with the fingers in one smooth movement. The faster this move, the better. If the stroke is too slow, the coal will extinguish itself by consuming all the available oxygen in the enclosed tube. Practice this movement a lot! In the beginning, I got an ember once in every 50 tries (mostly in one strike).

If everything went right, you can now see a smoldering ember in the tinder cup. Use a pin to transfer the ember to a tinder nest and blow this into a flame.

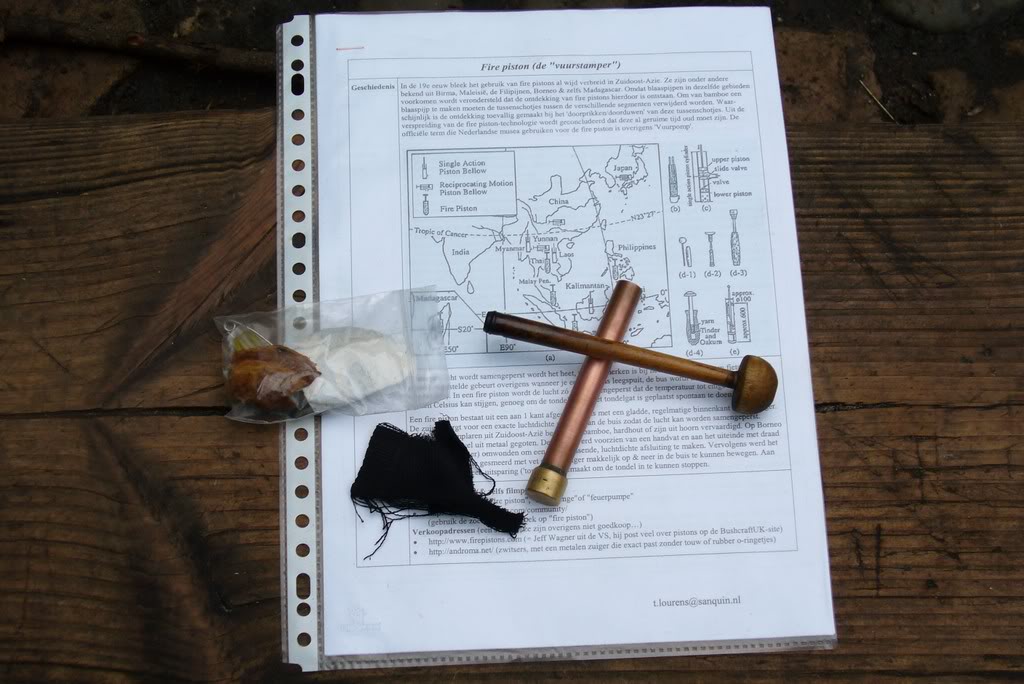

There you go, a simple homemade fire piston out of hardware shop material:

E-mail your comments to "Tom Lourens" in the Netherlands at t.lourens@sanquin.nl.

We hope the information on the PrimitiveWays website is both instructional and enjoyable. Understand that no warranty or guarantee is included. We expect adults to act responsibly and children to be supervised by a responsible adult. If you use the information on this site to create your own projects or if you try techniques described on PrimitiveWays, behave in accordance with applicable laws, and think about the sustainability of natural resources. Using tools or techniques described on PrimitiveWays can be dangerous with exposure to heavy, sharp or pointed objects, fire, stone tools and hazards present in outdoor settings. Without proper care and caution, or if done incorrectly, there is a risk of property damage, personal injury or even death. So, be advised: Anyone using any information provided on the PrimitiveWays website assumes responsibility for using proper care and caution to protect property, the life, health and safety of himself or herself and all others. He or she expressly assumes all risk of harm or damage to all persons or property proximately caused by the use of this information.

© PrimitiveWays 2013