Pressure Flaking

Powers quoted E. G. Waite's description of pressure flaking as he witnessed it during an even earlier day among the Klamath River Indians and the Indians of Central California.

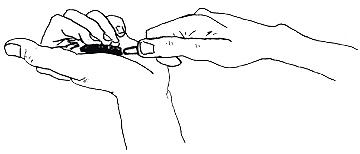

The palm of the left hand is covered with buckskin held in place by the thumb being thrust through a hole in it. The inchoate arrow-head is laid on this pad along the thick of the thumb, the points of the fingers pressing it firmly down. the instrument used to shape the stone is the end of a deer's antler, from 4 to 6 inches in length, held in the right hand. The small round point of this is judiciously pressed upon the edge of the stone, cleaving it away underward in small scales. The buckskin, of course, is to present the flesh from being wounded by the sharp scales. The arrow-head is frequently turned around and over to cleave away as much from one side as the other, and to give it the desired size and shape. It is a work of not little care and skill to make even so rude an instrument as an arrow-head seems to be, only the most expert being very successful at this business. Old men are usually seen at this employment.

The shaping and sharpening of the edge of a struck flake normally involved the technique of pressure flaking. Pope recorded that Ishi selected one of the pieces of obsidian he had struck to pressure flake into an arrowhead. It would be about 3 inches long, 1-1/2 inches wide, 1/2 inch thick and of appropriate shape and grain. Larger pieces were desirable for a gift or war arrow, a knife or spear; smaller and flatter for the oval heads he used for bear.

Ishi placed the obsidian in the palm of his left hand which he had protected with a pad of buckskin. He rested his left elbow on his left knee and with his left fingers held the flake securely against his palm. He gripped a large flaking too near the tip in his right hand as the wooden stick handle rested beneath his forearm, the butt against his ribs, for steadiness and for leverage. the left hand, protected by a double piece of buckskin, held the obsidian with all four fingers against the lower fleshy part of the palm, the edge of the flake parallel to the lines of his wrist, the thumb straight and parallel to his fingers. He engaged the sharp edge of the obsidian with the antler point, pressed forcefully upon the lower edge increasing the pressure downward and outward and clicked off a flake.

From personal experience I have found that the pressure often begins directly into the edge of the blank arrowhead but ends with a slow shift downward. The desired flake will detach when the edge of the cone of force begins to reach the lower surface of the blank, as the force shifts and increased in that direction. continued direct pressure into the edge only crumble it. perpendicular force alone merely nicks it. Trying to remove too large a flake from the side or excessive force to an end without supporting the whole piece will break the stone in half. Grinding the edges slightly with a piece of sandstone and leaving the grit helps the antler grip the edge. Incidentally, careful creation or preparation of platforms for the antler tine or striking stone by grinding in this way is a hallmark of modern flint knapping and was practiced by ancient masters as well.

In forming the arrow point Ishi took advantage of the natural outline of the stone. His first flakes from it were large, becoming smaller towards the end of his work. He turned the head over and over until the desired triangular shape had been formed. So as not to break the stem, a finer bone tool finished and notched the arrow point. Ishi wore a buckskin thumbpiece, and with his left index finger he held the arrowhead on this while with an awl-sized bone flaking tool he pressed out little notches against his thumb. Then he went back along the edge of the blade over and over again, flaking from point to base, producing fine, very sharp serration. A finished point was generally 2 inches in length 7/8 of an inch in width and 1/8 of an inch in thickness. It was larger for a war arrowhead.

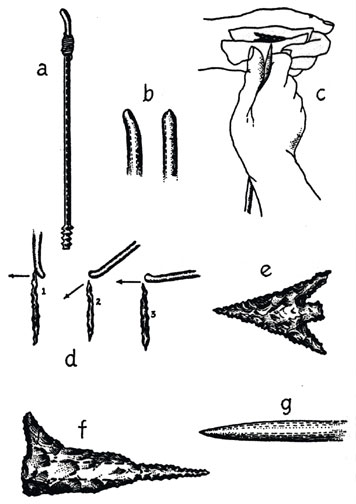

Examples from Ishi's knapping process. 1) Detached obsidian flake; 2) Arrow point initial stage; 3) Nearing completion; 4) Completed arrow point; 5) Small broad arrowhead of obsidian, 1" long, 11/16" wide, 1/8" thick; 6) Obsidian arrowhead, 2" long, 15/16" wide, 1/4" thick (Pope, 1918).

Ishi was a Yahi Indian from the foothills of the California Cascades. The Hupa of northwestern California used a flaking instrument similar to that described for Ishi and in essentially the same way. Goddard knew the last Hupa flint knapper. Old Roger worked the stone on a piece of buckskin held with his fingers on his left palm. The flaking tool held in his right was a piece of antler perhaps 7 inches long lashed for around 5-1/2 inches of its length to the side of a 15-inch stick handle. The handle would pass through the hand and along the forearm, enabling the knapper to develop considerable leverage, wrote Goddard.

Paul Schumacher's 1877 description of stone flaking from the "last arrow maker" of the Klamath River Yurok, whom he observed on the right bank near the mouth of the river, suggests there were alternatives in the precise positioning of the flake being worked (the edge perpendicular to the lines of the wrist rather than parallel as in the case of Ishi) as well as in flaking tools.

To work the flakes into the desired forms, certain tools are required, one of which is presented (A) in the figure above. It consists of a stick, which is in the form and thickness not unlike an arrow-shaft and about 1 foot in length, to one end of which a point is fastened, of some tough material, as the tooth of the sea-lion or the horn of elk, and even iron among the present Klamaths, although the rock does not work as well, and brittles where the edge ought to be sharp. The point (B of the figure) is represented in natural size to better illustrate its beveled curve, which form admits a gradual pressure to a limited space of the edge of the sherd. During the operation, the rock is partly inwrapped in a piece of buckskin for better manipulation, its flat side resting against the fleshy part of the thumb of the left hand, only the edge to be worked (C) being left exposed. The tool is worked with the right hand, while the lower part of the handle, usually ornamented, is held between the arm and the body so as to guide the instrument with a steady hand. The main movement are shown in figure (D). With the first movement as illustrated, larger flakes are detached, and the rock is roughly shaped into the desired form; while with the second movement long flakes are broken, which frequently reach the middle of the sherd, producing the ridge of the points or knives; finally with the third movement the smaller chips of the cutting edge are worked. The work proceeds from the point, the more fragile part of the weapon toward the stronger end, as illustrated by the unfinished bore, the form of which, as frequently found, is shown by dotted lines. To work out the barbs and projections of the arrow or spear points (E,F), a bone needle (G) is used, as pictured in natural size in the figure, about 4 to 5 inches long, without a shaft.

Gayton wrote the Western Mono held the obsidian in the left hand beneath the straightened thumb and bent index finger and braced by the middle finger. The buckskin guard was not always used. They detached flakes with the little bone of the deer's dew toe. The antler tine in a pressure-flaking kit from the Tejón Pass area, probably Kitanemuk (collected in 1901 by J. W. Hudson and found today in the Field Museum), is bluntly pointed, nearly an inch thick and almost 6 inches long. Ishi used a piece of antler, neither too sharp nor too blunt, bound to a stick about a foot long (actually the length of the distance from the elbow to his extended middle finger), but he employed a much smaller tool for the finer work of arrowhead notches. His flaking tools were pointed almost like a screwdriver, according to Pope, only rounded instead of square at the tip, filed quite sharp.

Ishi kept completed heads in a small skin bag. Often these heads were not attached until a few hours before the hunt. Heated pine resin was applied to the notched end of the arrow, the head was set in and the resin molded around the base. When it cooled, three wraps of sinew were made criss-cross, up and about each notch and around the shaft, then continued around the arrow for half an inch just below the arrowhead. Once dry, the binding was polished lightly with sandstone.

Ishi told Pope that men made arrowheads in secluded spot away from camp. They daubed their faces with black mud and did not talk. When a flint fragment flew in his eye, Ishi pulled down his lower lid with his left forefinger -- he did not blink or rub the lid -- he bent over, looked at the ground and gave himself a forceful thump on the crown with his right hand to dislodge the sliver of stone. Modern knappers wear safety glasses.

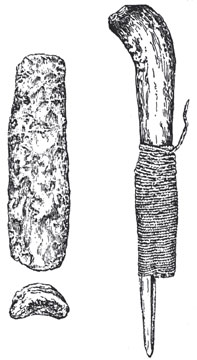

Hupa pressure flaker, antler lashed to crooked handle, collected by Lieutenant P. H. Ray during the 1880s. This was used to make arrowheads from flint or obsidian for war or big game. The ball of the handle would rest in the right palm as the antler pressed on flint held in the palm of the left hand protected by a buckskin pad. According to Ray, the flakes were first knocked from a larger piece with a section of deer antler (piece pictured to the left longitudinally and in cross section). The hard antler was used between the hammer and core as a kind of cold chisel. It detached high quality flakes (Mason, 1894).

Aboriginal California bone-pointed pressure flakers: top, from the Yurok, 17-3/8" long (University of California collection, pictured in Pope, 1918); below, Northern Maidu, 11-1/2" long (drawn in Dixon, 1905). Simpler flakes, not fixed to a wooden handle, were also used. Those found by M. Leon De Cessac on San Nicholas and San Miguel islands during the nineteenth century were of a heavy mammal bone, a rib and split rib, and a sea mammal penis bone. Short sections of deer antler were often employed as flakers in California.

The article is from the book, entitled "Survival Skills of Native California" (ISBN 0-87905-921-4), by Paul Douglas Campbell. Permission to use the article on the PrimitiveWays website was given by Mr. Campbell. Paul Campbell can be contacted through his publisher, Gibbs Smith, P.O. Box 667, Layton, Utah 84041.

We hope the information on the PrimitiveWays website is both instructional and enjoyable. Understand that no warranty or guarantee is included. We expect adults to act responsibly and children to be supervised by a responsible adult. If you use the information on this site to create your own projects or if you try techniques described on PrimitiveWays, behave in accordance with applicable laws, and think about the sustainability of natural resources. Using tools or techniques described on PrimitiveWays can be dangerous with exposure to heavy, sharp or pointed objects, fire, stone tools and hazards present in outdoor settings. Without proper care and caution, or if done incorrectly, there is a risk of property damage, personal injury or even death. So, be advised: Anyone using any information provided on the PrimitiveWays website assumes responsibility for using proper care and caution to protect property, the life, health and safety of himself or herself and all others. He or she expressly assumes all risk of harm or damage to all persons or property proximately caused by the use of this information.

© PrimitiveWays 2013